ICS 29.240

K43

Record Number: 31117-2011

DL

China Electric Power Industry Standard

DL/T 687-2010

Replace DL/T 687-1999

General Specification for Preventing Electric Mal-operation System with Computer

2011-01-09 Release 2011-05-01 Implement

National Energy Administration Release

Preface

DL/T687-1999 “General specification for Preventing Electric Mal-operation Device with Computer” is an electric standard to meet the common needs of both users and manufactures which has no corresponding standard technical reference in and out of China. With the development of high technology including computer technology, monitoring technology, communication technology and the increase of the users’ needs, the standard needs to be revised.

Compared to DL/T687-1999, this standard has the following main changes:

a)Standard name. With the new extension of product functions and the implementation of the nobody watching mode in substation, the mal-operation preventing device of the main station and plant station, the plant station and plant station, the station control layer, spacer layer, device layer form the system, which can adapt to different types of device and requirements of different operating ways. The standard name will be " System " instead of " Device ".;

b)Section. The standard adds “Selected Guide for Preventing Electric Mal-operation System”, “Information provided when Inquiring, Bidding and Ordering”, “Safety”, “Impact on the Environment” and other sections and deletes “Basic Classification” in DL/T687-1999 standard.

c)Range. The standard changes the fact that SL/T687-1999 applies to “”High Voltage Switchgear” to that it applies to “High Voltage Switchgear and its Attachments”.

d)Normal and special using conditions. The standard uses second chapter in DL/T593-2006” Common Technical Requirements of High-voltage Switchgear and Control Device Standards”.

e)Terms and definitions. The standard modifies the terms and definitions like preventing electric mal-operation system with computer, preventing host, simulation terminal accord to the development of new technology. At the same time, it adds the terms and definitions of earth lock, mandatory lock, remote controlling and locking device and so on.

f)Rated value. The standard modifies the rated value of mal-operation preventing host, computer key, mechanical encoded lock and earth lock.

g)Design and structure. The standard modifies the design and structure of preventing electric mal-operation system with computer, preventing host, computer key and encoded lock.

h)Type test

1)The function test adds the communication device and remote controlling device.

2)Locking and unlocking test adds content relevant with the remote control locking device.

3)Insulation test adds communication device and remote control device and deletes the computer key.

4)Power adaptability test increases test requirements of communication device.

5)It divides mechanical encoded locks into fixed lock and padlocks and comes up with requirements of fastness test.

6)Electromagnetic compatibility test adds communication device and remote control locking device. Projects, content and requirements of the tests refer to GB/T17626” Electromagnetic Compatibility Test and Measure Technology”. The projects are changed to anti-jamming degree test of static discharging, electrical fast transient/burst immunity test, surge immunity test, power frequency magnetic field immunity test, and oscillatory wave immunity test accord to the standard.

7)The standard uses protection class test instead of rain test. The test method is based on GB4208” Enclosure Protection (IP encoded)”.The class is IPX4.

i)Selection guide. The standard adds this section and raises the selection guide of rated value, design and structure of the mal-operation preventing system.

j)Information provided when inquiring, bidding and ordering. The standard adds section about that.

k)Safety. The standard adds this section and raises requirements relevant with that.

l)Impact on the environment. The standard adds this section and raises that manufacture should provide information about that.

The standard will replace PL/T 687-1999.

The standard is raised by Chinese Electricity Council.

The standard is drafted by Chinese Electric Power Research Institute.

Participated in the drafting of this standard : State Grid Corporation , Beijing Electric Power Company, Tianjin Electric Power Company, Shanghai Electric Power Company , Jiangsu Provincial Power Company , Fujian Electric Power Company, Hubei Electric Power Company , China Power Engineering Consulting Group Corporation, Guangdong Power Grid Corporation Electric Power Research Institute , Xi'an High Voltage Apparatus Research Institute , Zhuhai YouTe power Technology Co., Ltd., Zhuhai GongChuang electrical safety technology Co., Ltd., Nanyang ChuanGuang power Technology Co., Ltd. , Hubei XuDa Electric Power technology Co., Ltd. , Nanjing Shengtai DMS Power System Co., Ltd. , Tianshui ChangCheng Switchgear Co., Ltd. .

The main drafters: Yuan Dulu, Chen Jingcheng, Yang Kun.

Participated in the drafting: Lu Maode, Wu Jing, Tian Enwen , Jing Xiao-ping , Li Shufen, Xiao Yongli , Wu Dong, Wang Sheng , Zhu Genliang , Tian Weiyun , Xie Xiaowei , Ma Binglie , Wang Yu , Cao Yuan , Mao Yaohong, Lu Tianjian .

The standard is released first on Feb.24th in 2000. This time is the first time to be revised.

The advices in the executing progress will be sent to Chinese Electricity Council Standard managing center.

National Energy Administration

General Specification for Preventing Electric Mal-operation

System with Computer

DL/T 687-2010

1.Range

The standard sets the using condition, rated value, design and structure, test and selection guide and other content of preventing electric mal-operation system with computer.

The standard adapts to high-voltage device and its attachment in the electric system.

2.Standardized Reference

The following references are very important to the application of this standard. The references which have date are applicative, while the latest type of references which have no date (including all modification) is applicative.

GB4208 “Enclosure Protection” (IP encoded)

GB/T2423.1 “Environment Test of Electronic Products for Electrician” Part2: Test Method Test A: Low Temperature

GB/T2423.2 “Environment Test of Electronic Products for Electrician” Part2: Test Method Test B: High Temperature

GB/T2423.4 “Environment Test of Electronic Products for Electrician” Part2: Test Method Test Db:

GB/T2423.16 “Environment Test of Electronic Products for Electrician” Part2: Test Method Test J and guide: Mildew

GB/T2423.17 “Environment Test of Electronic Products for Electrician” Part2: Test Method Test Ka:

GB/T2423.27 “Environment Test of Electronic Products for Electrician” Part2: Test Method Test L: Sand test

GB/T5465.2 “Graphs and Signs for Electric device” Part2: Graphs and Signs

GB/T9813 “General Standard for Microcomputer”

GB/T17626.2 “Electromagnetic Compatibility Test and Measure Technology Electrostatic Discharge Immunity Test”

GB/T17626.4 “Electromagnetic Compatibility Test and Measure Technology Electrical Fast Transient Burst Immunity Test”

GB/T17626.5 “Electromagnetic Compatibility Test and Measure Technology Surge (Impact) Immunity Test”

GB/T17626.8 “Electromagnetic Compatibility Test and Measure Technology Frequency Magnetic Field Immunity Test”

GB/T17626.12 “Electromagnetic Compatibility Test and Measure Technology Oscillatory Waves Immunity Test”

DL/T593-2006 “Common Technical Requirements of High-voltage Device and Controlling Device Standard”

DL/T860 “Communication Network and System in Substation”

DL/T879 “Portable Earth and Earth Cutting-out Device for Electric Work”

3.Normal and Special Using condition

DL/T593-2006 Section2 is applicative.

4.Terms and Definitions

The following terms and definitions are applicative to this standard.

4.1Preventing Electric Mal-operation System with Computer

It’s a system which uses computer, measuring and controlling, communication and other technologies and is used for high-voltage and its attachments. It mainly consists of mal-operation preventing host, simulation terminal, computer key, communication device, mechanical encoded a lock, electrical encoded lock, earth lock, remote locking device and other parts.

4.2Preventing Mal-operation Host

It’s the main controlling unit of computer preventing system and made up with the computer as well as mal-operation preventing software. It can write and store preventing rules in advance, accept the operating procedure of simulation terminal, send the eligible procedure to the computer or control the remote lock to unlock, and then receive information back from computer key operation.

4.3Simulation Terminal

It has primary device main wiring picture which can show the condition of the primary device. It does simulating operation, sends operating procedure to mal-operation preventing host and presents the operating result. For example: simulation screen, computer displayer and so on.

4.4Smart-Key

It is a component which receives the operating procedure of mal-operation preventing host, distinguishes and control encoded lock, sends operating order back to the host.

4.5 Encoded Lock

It’s a lock which uses number encoded structure, achieves locking and unlock accord to the operating order of acomputer key or mal-operation preventing host.

Encoded locks are divided into mechanical and electrical encoded locks in the aspect of the method and are distinguished into fixed locks and padlocks. Encoded locks contain earth locks and remote controlling locks.

4.6 Mechanical Encoded Lock

It is the encoded lock which uses mechanical method to lock or unlock the high-voltage device and its attachments.

4.7 Electric Encoded Lock

It is the encoded lock which uses electrical method to lock or unlock the operating circuit of high-voltage device and its attachments.

4.8 Earth Lock

It has number encoded structure and is used in earth error preventing operation. It is the mechanical lock which satisfies the requirements of preventing connecting earthing device for work or closing the earth switch with electricity and preventing closing breaker or disconnector with earthing device for work or earth switch. It consists of earth head and ground pile.

4.9 Remote Control Locking Device.

It is a component which is controlled by mal-operation preventing host and used to achieve forced locking for remote controlling operation. It consists of locking relay and electric encoded lock.

4.10 Releasing Key

It is used for unlocking.

4.11 Preventing Mal-operation Procedure

It’s the operating order set by the operating rules.

4.12 Locking

It’s not the mal-operation preventing procedure and can’t be operated.

4.13 Unlocking

It unlocks through the order of computer key and mal-operation preventing host accord to the procedure.

4.14 Releasing

It isn’t limited by mal-operation procedure and gets rid of unlocking by unlocking key.

4.15 Forced Locking

It connects the points or locks in series in the electric operating circuit of device. In addition, it installs locks controlled by mal-operation preventing host. It’s not the error preventing procedure and cannot be operated.

4.16 Null Procedure

In the operating process of preventing procedure, if the object controlled by encoded lock cannot change from the primary position to the specified position, then the next operation can go on.

4.17 Skipping Operation

When the operation goes to any step, the operation except the current operation can be done.

5.Rated Value

5.1Mal-operation Host

a)Rated voltage

1)AC: 220V, allow 85%-110% of deviation, frequency50Hz

2)DC:110*(1±10%)V or 220*(1±10%)V

b)Information amount of switch: (n≧12, n is integer)

5.2Simulation Terminal

Component life used for simulation screen: ≧50000 times

5.3Computer Key

a)Rated voltage: ≦24V

b)Number of operating tickets received at one time: ≧1000

c)Memory Capacity: ≧1024KB

d)Number of identified encoded locks: (n≧12, n is integer)

e)Continuous operating times with no charge: ≧256

f)Continuous work time of charge: ≧8h

g)Life: ≧50000 times

5.4Communication Device

a)Rated voltage

1)AC: 220V, allow 85%-110% of deviation, frequency50Hz

2)DC:110*(1±10%)V or 220*(1±10%)V

b)Number of communication terminal: Ethernet interfaces ≧2

5.5Mechanical Encoded Lock

a)Encoded value: (n≧12, n is integer)

b)Life: 10000 times

5.6Electric Encoded Lock

a)Encoded value: (n≧12, n is integer)

b)Rated voltage

1)AC:220V, allow 85%-110% of deviation, frequency50Hz

2)DC:110*(1±10%)V or 220*(1±10%)V

c)Rated current: 1, 2.5,5A

d)Life: 10000 times

5.7Earth Lock

a)Rated short-time tolerance current (rms): 8kA

b)Rated peak tolerance current (peak): 20kA

c)Rated short-circuit duration: 3,4s

d)Cross-section of copper conductor: ≧120

e)Encoded value: (n≧12, n is integer)

5.8Remote Control Locking Device

a)Rated voltage

1)AC: 220V, allow 85%-110% of deviation, frequency50Hz

2)DC:110*(1±10%)V or 220*(1±10%)V

b)Locking points: (n≧12, n is integer)

c)Life of locking interfaces: 10000 times

5.9Unlocking Key

Life: ≧10000 times

6 Design and Structure

6.1 Preventing Electric Mal-operation System with Computer

6.1.1 General Requirements

Preventing electric mal-operation system with computer should achieve the locking function in the main station and plant station, the plant station and plant station, the station control layer, spacer layer, device layer and meet the preventing requirements of different types and operating ways of device. Its design should not affect the normal operation of electric device and ensure the mechanic, electric and information processing performance. The system should use the separate power circuit. When other devices or systems go wrong, it can still work. The rules and data of the system should be prepared separately, and can be printed or checked.

6.1.2 Function

a) Preventing opening or closing the breaker by mistaken; Preventing opening or closing the disconnector with load by mistaken; Preventing connecting earthing device for work or closing the earth switch with electricity; Preventing closing breaker or disconnector with earthing device for work or earth switch; Preventing getting into the electric interval by mistaken.

b) Simulating, producing, transmitting, managing operating tickets correctly.

c) Collecting, dealing with and transmitting information correctly.

d) Locking smoothly; no vacant procedure; alarming through light, sound or voice. Sound or voice alarm should not less than 45dB 50cm away from the source. Light alarm should be seen easily.

e) Electromagnetic compatibility.

f) RAM should meet all operating requirements.

g) Forced locking of operating locally and remote controlling operation.

h) Preventing getting into the electric interval by mistaken under the condition of overhaul.

i) Having interfaces with high-voltage electric displaying device.

j) Timing, self-checking

6.1.3 Structure

a) Components of the product should be installed firmly. The weld should be welded. Components should be flexible and reliable.

b) Components which have the same rated parameter and structure should have interchangeability.

c) Each component should follow its standard except when this standard has other rules.

d) Materials should meet the needs of long-term work and using condition.

6.1.4 Isolating Level

Wiring terminal should bear the 2000V, 1min frequency voltage and has no breakdown.

Attention: With the use of electronic components, this test can use different procedures and data due to the agreement between manufacture and users.

6.1.5 Appearance

The surface of the product should not be damaged, transformed and polluted. The plating surface should be equal without foaming, chapping, falling off and abrading. Components of metals should not rust or be damaged. The part people may touch should have no thorn.

6.2 Mal-operation Preventing Host

6.2.1 General Requirements

The technical requirements should meet GB/T9813 standard.

6.2.2 Function

a) Edit in advance and store mal-operation preventing procedure.

b) Multi-task operation.

c) Exchange information in dual directions with simulation terminal, computer key, and remote controlling lock device.

d) After the power is cut, the procedure edited in advance and other information should not be changed or lost.

e) The mal-operation preventing host which is able to gather the information can also receive the information of remote device and high-voltage electric device with its attachment. The information is correct and intact.

f) Function of simulation show in advance, five-prevention logic judgments and operation tickets production.

g) The picture and the sign should meet GB/T5465.2 standard.

6.2.3 Encode

The codes which are controlled by the common computer cannot repeat.

6.2.4 Power

The power circuit of the mal-operation preventing host should be separated with protection and control circuit in substation to prevent disturbance.

6.3 Simulation Terminal

6.3.1 Function

a) Simulation operation. In the operation, the component (or graph present) should open or close at the right position. The interface should be reliable.

b) Transmission. After simulation, the correct operating procedure will be sent to the mal-operation preventing host. Wrong operation will cause the light, sound or voice alarm.

c) Position display. It can show the right opening or closing position of high-voltage device and attachments. When computer key does arbitrary operation, the screen should display the operation correctly through proofreading.

6.3.2 Function

It has or displays the main wiring diagram of primary device.

6.4 Computer Key

6.4.1 Function

a) Receive operating procedure of the mal-operation preventing host correctly.

b) Distinguish the encoded lock correctly, lock smoothly, flexibly. Lock with light, sound or voice alarm during the wrong operation.

c) Proofreading function of sending the opening or closing position of high-voltage electric device and its attachments through distinguishing encoded lock.

d) After cutting power or using new charge, the storing operating procedure and other all information won’t be changed or lost.

e) Lock and give prompt when it goes wrong or the power is cut.

f) Record information of operating process.

6.4.2 Displaying Screen

a) Set the displaying screen at the obvious position and show the current operating number and content. Writing should be clear for watching. Display the checking project if user needs.

b) With background light to make the characters clear in strong light or in the dark.

c) Display the charge volume.

6.4.3 Structure

a) Volume and quality should meet the needs of easy-taking.

b) Function of preventing rain; Meet the needs of outdoor operation

c) Outer skin and structure should bear the damage of falling.

d) The solution of preventing falling or knocking should be considered.

6.4.4 Encode

a) Structure and theory should ensure the correctness and reliability of encoding.

b) No repeat of encoding; Operate without mistake.

6.4.5 Locking Mechanism

Encoded lock should not be operated when locking. Encoded lock should be reliable, flexible, and smooth when unlocking.

6.4.6 Cell

Meet the needs of continuous operating times and working time; Ensure proper functioning of computer locking mechanism operation, screen displaying, alarming and background light.

6.5 Communication Device

Communication device which has the ability of communicating with other systems should meet the rules of DL/T860.

6.6 Encoded Lock

6.6.1 Function

a) Mechanical encoded locks should keep the lock plug on the locking position under the condition of locking.

b) Electrical encoded locks should do compulsory locking to high-voltage electric device in the way of connecting in series.

c) Unlocking smoothly in the normal operation; Locking when wrong operation happens.

6.6.2 Structure

a) Simple, reliable, flexible, no locking, convenient maintaining.

b) Prevent moist, dust, corrosion; Outdoor encoded locks should have good sealing function, the special using condition should meet the relevant standard.

c) Mechanical encoded locks should meet the requirements of producing locks. Lock plug should bear the intensity of the high-voltage device.

d) Electrical encoded lock should meet the requirements of insulation intensity.

6.6.3 Encode

The same as 6.4.4.

6.7 Earth Lock

6.7.1 Function

Besides 6.6.1 a), c), it should have:

a)Bearing ability of short-time or peak current when electric device safety earth and rated current is cut.

b)Locking function of preventing connecting earthing device for work with electricity, Preventing closing breaker or disconnector with earthing device for work.

6.7.2 Structure

Besides 6.6.2 a),b),c), it also has the features as:

a)Structure design should match up with the easy-taking earth and earth short-cut device in electric operation.

b)The interfaces should interface with ground pile well. The interfaceing area shouldn’t be less than 120. The ground pile and earth objects should weld firmly.

6.7.3 Encode

The same as 6.4.4.

6.8 Remote controlling locking device

6.8.1 Function

Besides 6.6.1 b), c), it also has:

a)Remote controlling unlocking function.

b)Function of unlocking locally by computer key.

6.8.2 Structure

Besides 6.6.2 a),b),d), it also has the features as:

a)Interfaces of locking relays touch well. The operation is reliable. The matched relays should correspond with relevant standards and rules.

b)Locking relays should connect with electrical encoded lock well. The whole structure should be firm.

6.8.3 Encode

The same as 6.4.4.

6.9 Unlocking Key

Preventing electric mal-operation system with computer should be matched with unlocking keys which should be flexible and have no locking

6.10 Nameplate

Preventing electric mal-operation system with computer and its functional components should be installed with a clear and durable nameplate. Nameplate outdoor shall withstand climate impact and corrosion.

Nameplate shall contain the following:

a)manufacturer's name or trademark

b)type of production

c)manufacturing date

d)serial number

e)rated parameters

7 Type Test

7.1 General Provisions

Type tests are intended to verify whether preventing electric mal-operation system with computer meets the requirements of production.

Type tests shall include all functional components of preventing electric mal-operation system with computer. The components should match the chart.

The terms of the type test include:

a)Inspection of appearance and structure (seen in 7.2)

b)Simulated operation test (seen in 7.3)

c)Function verification test (seen in 7.4)

d)Locking and unlocking test (seen in 7.5)

e)Insulation test (seen in 7.6)

f)Power adaptability test (seen in 7.7)

g)Fastness test of locks (seen in 7.8)

h)Test of continuous operation (seen in 7.9)

i)Electromagnetic compatibility test (seen in 7.10)

j)Environment test (seen in 7.11)

k)Protection class test (seen in 7.12)

l)Dropping test (seen in 7.13)

m)Short-time and peak withstanding current test (seen in 7.14)

n)Mildew test (seen in 7.15)

o)Salt spray test (seen in 7.16)

p)Dust test (seen in 7.17)

Type tests should be carried out on the following products:

-New production

-Trial production in different plants

-When the products has changes in design, workmanship or materials, the correspond type test should be done.

-The productions made frequently should carry out the type test every 5 years.

7.2 Inspection of Appearance and Structure

7.2.1 Tested Object

The tested object is preventing electric mal-operation system with computer.

7.2.2 Integrity Test

The integrity of preventing electric mal-operation system with computer should meet technical demands of products and requirements of chart.

7.2.3 Appearance Test

Through eyeballing, the appearance should meet 6.1.5, and nameplate should meet 6.10.

7.2.4 Structure Test

Through eyeballing and ruler measuring, structure should meet 6.1.3, moreover, mal-operation preventing host should meet 6.2.4, simulated terminal should meet 6.3.2, computer key should meet 6.4.3, encoded lock should meet 6.6.2, and earth lock should meet 6.7.2.

7.3 Simulated operation Test

The tested object is mal-operation preventing host and simulated terminal.

In the test, normal operation and five wrong operation are simulated for 3 times, which should obey the rules of 6.1.2 a), b), 6.2.2 a), b), f) and 6.3.1 a).

7.4 Function verification Test

7.4.1 Information Transmission

The tested object is mal-operation preventing host, simulated terminal, computer key, communication device and remote controlling locking device.

Inserting computer key to achieve the connection among mal-operation preventing host, simulated terminal and computer key, and transmitting entire operating procedure for three times in the direction of “simulated terminal- mal-operation preventing host- computer key and/or remote controlling locking device” or “computer key and/or remote controlling locking device- mal-operation preventing host- simulated terminal” should obey the rules of 6.1.2 c), f), 6.2.2 c), 6.3.1 b) and 6.4.1 a).

The device which has the function of gathering information at real time shall verify the function of receiving information of remote device, high-voltage device and attachments. The information are received 3 times. It should obey the rules of 6.2.2 e).

The communication device goes through the information transmission test, which should meet the rules of 6.5.

7.4.2 Position Display of High-voltage Electric device and Its Attachments

The tested object is mal-operation preventing host, simulated terminal, computer key and encoded lock.

According to the normal operating procedure, computer key operates on the arbitrary components of encoded lock for 3 times (including doing complete operation for one time). After each operation, the steps should be transmitted back to the mal-operation host and simulated terminal. The result should meet the rules of 6.3.1 c) and 6.4.1 c).

7.4.3 Alarm

The tested object is mal-operation preventing host, simulated terminal, computer key and encoded lock.

In the test, five wrong operations and skipping step operation are tested in the ways of using simulated terminal to simulate and trying to use computer key to unlock the encoded lock. The alarm of simulated terminal and computer key should obey the rules of 6.1.2 d), 6.3.1 b) and 6.4.1 b).

7.4.4 Memories of Losing Electricity

The tested object is mal-operation preventing host and computer key.

Computer key gets operating procedure from mal-operation preventing host, in the operating process, the host cut the power, the charge is taken out from computer key,, then everything renewed after 1 hour. The test goes for three times and should meet the rules of 6.2.2 d), 6.4.1 d).

7.4.5 Computer Key Display and Background Light

Open the power switch of computer key, check the displaying screen. Turn on the background light and observe in the dark or in the sunlight. It should obey rules of 6.4.2.

7.4.6 Unlocking

Use the unlocking key to unlock every kind of encoded lock. Each kind of encoded lock should be tested for 3 times. It should obey the rules of 6.9.

7.5 Locking and Unlocking Test.

7.5.1 Tested Object

The tested object is mal-operation preventing host, simulated terminal, computer key, mechanical encoded lock, electrical encoded lock, earth lock and remote controlling locking device.

7.5.2 Mechanical Encoded Lock, Electrical Encoded Lock, Locking and Unlocking Test

7.5.2.1 Preparation for computer key test. Use computer key to receive enough procedures which meet the operating requirements of encoded lock from the mal-operation preventing host.

7.5.2.2 Unlock. Check the numbers of encoded locks due to the current operating step displayed on the screen of computer key and unlock by computer key. Operate in order for 3 times.

7.5.2.3 Lock.

a) Test five wrong operations, each of which is operated for 3 times.

b) Test skipping step, simulate arbitrary condition for 3 times, and operate one time under each condition.

c) Test computer losing power (cutting power or taking out of the charge), select three encoded locks arbitrarily and operate each of them for one time.

7.5.2.4 Test judging basis. If the result meets the rules of 6.1.2 a), 6.4.1 b), e), 6.4.4, 6.4.5, 6.6.1, the test succeeds.

7.5.3 Locking and Unlocking Test of Remote Controlling Device

7.5.3.1 Test preparation of mal-operation preventing host. After simulated operation in advance, the mal-operation preventing host creates enough procedures which satisfy the operation of tested remote controlling locking device.

7.5.3.2 Unlocking. Check the number of remote controlling locking device accord to the current step displayed on the host, start the device and operate three times on each device in order.

7.5.3.3 Locking.

a) Test wrong operation for 3 times.

b) Test skipping step for 3 times.

c) Test computer losing power (cutting power) for 3 times.

7.5.3.4 Test judging basis. If the result meets the rules of 6.1.2 a) which are preventing opening or closing the breaker by mistaken and preventing opening or closing the disconnector with load, the rules of 6.4.1 b), e), 6.4.4, 6.4.5 and 6.6.1, the test succeeds.

7.6 Insulation Test

7.6.1 General Requirements

The tested objects are mal-operation preventing host, communication device, electrical encoded locks and remote controlling locking device.

The tested part is AC 220V and/or DC 110V, 220V earthing device for work terminal.

7.6.2 Insulation Resistance Measurement

Measured by insulation resistance meter which outputs 1000V voltage.

a)Under normal condition: ≧1000M

b)After Cyclic damp heat test: ≧10 M

7.6.3 Frequency Voltage Withstanding Test

Frequency voltage value in 1 minute:

a)Under normal condition: 2000V

b)After Cyclic damp heat test: 1600V

In the test, the object should have no broken phenomenon.

Attention: due to the use of electronic components, the pressure test of this part may use different test procedures and values accord to the agreement between the manufacturer and the users.

7.6.4 Measurement of Revealed Current

Frequency voltage value:

a)Under normal condition: 2000V

b)After Cyclic damp heat test: 1600V

Revealed current: ≦1mA

7.7 Adaptability Test of Power

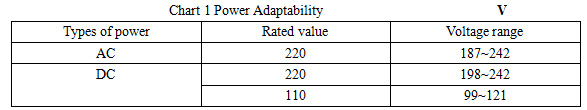

Test the mal-operation preventing host and communication device accord to chart 1 for 3 times with AC/DC voltage. It should meet the rules of 6.2.2 and 6.5.

7.8 Fastness Test of Locks

The tested objects are all kinds of encoded locks. Install the encoded locks accord to the reality.

a)Fixed lock:

1)After adding 500N strength to the lock, bolts and lock body should not be deformed, loosed and damaged.

2)After the bolt is totally out, add 500N strength vertically to the end of the bolt, and the bolt should not be deformed, loosed and damaged.

3)Under locking condition of the bolt, pull the bolt with normal strength, the bolt should not change position.

b)Padlock:

1)Under locking condition of the bolt, add 500N strength vertically to the end of the bolt, and the bolt should not be deformed, loosed and damaged.

2)Under locking condition of the bolt, pull the bolt with normal strength, the bolt should not change position.

7.9 Continuous Operation Test

7.9.1 Continuous Operation Test of Mechanical Lock

Test various mechanical encoded lock and earth lock respectively, take one in each kind of locks, test should not be done for less than 10000 times.

Attention: Lock bolt should complete a circuit, which is seen as “one time”.

In the test, locks should work well and can be lubricated. The computer key can be charged but cannot be fixed and the components cannot be changed. After the test, all components should not be deformed, loosed damaged, and should meet the rules of 6.6.1 a), c).

7.9.2 Continuous Operation Test of Electrical Locks

Test all kinds of electrical encoded locks and remote locking device separately with computer, take one in each kind of locks, test should not be done for less than 10000 times.

Attention: Electrical interface complete one time of connecting or breaking, which is seen as “one time”.

Voltage and current value of electrical circuit are based on technical condition of products.

In the test, locks should work well and can be lubricated. The computer key can be charged but cannot be fixed and the components cannot be changed. After the test, all components should not be fevered, loosed damaged, and should meet the rules of 6.6.1 b), c).

7.9.3 Continuous Operation Test of Computer Key

Test all kinds of encoded locks separately with computer key, test should not be done for less than 50000 times.

In the test, unlocking component of computer key should work well and can be lubricated. The computer key can be charged but cannot be fixed and the components cannot be changed. After the test, all components should not be deformed, loosed damaged, and should meet the rules of 6.4.5.

Attention: this test can be done along with 7.9.1 and 7.9.2.

7.9.4 Continuous Working Time and Operation Test of Computer Key without Charging

Test all kinds of encoded locks separately with computer key.

Computer key receives no less than 256 steps of procedures to operate the encoded locks. Every step will be displayed on the screen. After 250 times of operation, continue the remaining operation when the condition of starting up reaches the continuous working time of charge in the technical rules. After the test, the charge of computer key should obey the rules of 6.4.6.

Attention: this test can be operated along with 7.9.1 and 7.9.2.

7.9.5 Continuous Operation Test of Motion Components in Simulated Terminal

Continuous operation of motion components in simulated terminal should not be done for less than 50000 times. After the test it should meet the rules of 6.3.1 a).

7.9.6 Continuous Operation Test of Unlocking Key

Test all kinds of encoded locks separately with unlocking key. The test should be done for more than 10000 times. After the test it should meet the rules.

7.10 Electromagnetic Compatibility Test

7.10.1 General Requirements

The tested objects are mal-operation preventing host, simulated terminal, computer key, communication device, all kinds of encoded locks and remote controlling locking device.

The test requirements are checking accord to 7.4.1 and 7.5 in Electromagnetic compatibility test. In the test, in 7.4.1 each transmits information for one time and in 7.5 each kind of encoded locks should be operated for one time. The operation should goes successfully.

7.10.2 Anti-jamming Degree Test of Static Discharging

The tested method is based on GB/T 17626.2. The test grade is three: interface discharging ±6kV, air discharging ±8kV.

7.10.3 Electrical Fast Transient Burst Immunity Test

The tested method is based on GB/T 17626.4. The test grade is three: signal port:±1kV, charge port ±2kV.

7.10.4 Surge immunity test

The tested method is based on GB/T 17626.5. The test grade is three: starting test voltage: ±2kV.

7.10.5 Power Frequency Magnetic Field Immunity Test

The tested method is based on GB/T 17626.8. The test grade is three: intensity of magnetic field: 10A/m.

7.10.6 Oscillatory Wave Immunity Test

The tested method is based on GB/T 17626.12.The test grade is three: different-mode voltage is 1.0kV, common-mode voltage is 2.5kV, oscillation frequency is 1MHz.

7.11 Environmental Test

7.11.1 General Requirements

The tested objects are mal-operation preventing host, simulated terminal, computer key, communication device, all kinds of encoded locks, earth locks and remote controlling locking device. The test is done accord to the different condition in the door or outdoor.

In the test, initial and final tests are done based on the rules of 7.2.3, 7.4.1 and 7.5. Before the final test there is 2 hours of recovering time. In 7.4.1 each transmits information for one time and in 7.5 each kind of encoded locks should be operated for one time. The operation should goes successfully. The locks are reliable.

Under special condition, rule 2.2 in DL/T 593-2006 is considered.

7.11.2 Low Temperature Test

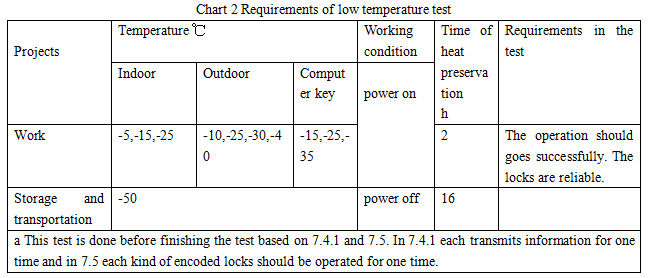

Put the tested objects in the low temperature tested box, do the test based on DB/T 2423.2, the test requirements can be seen in chart 2.

7.11.3 High Temperature Test

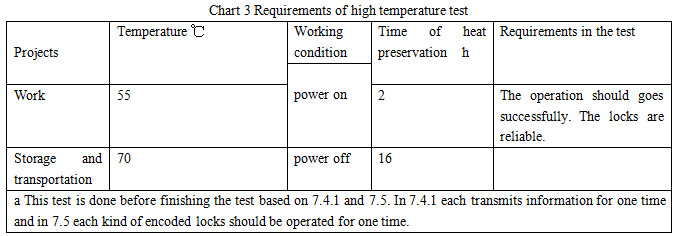

Put the tested objects in the high temperature tested box, do the test based on DB/T 2423.2, the test requirements can be seen in chart 3.

7.11.4 Cyclic Damp Heat Test

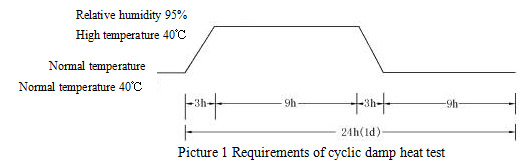

Put the tested objects in the cyclic damp heat box, do the test based on DB/T 2423.4, the test requirements can be seen in Picture 1, severity is 2 days. In the second warm and wet period after cyclic damp heat, the tested object goes through the cyclic damp heat test with 2 hours of charging. The middle test is based on 7.4.1 and 7.5 in this period. In 7.4.1 each transmits information for one time and in 7.5 each kind of encoded locks should be operated for one time. The operation should goes successfully. The locks are reliable. The objects should go through the insulation test ruled in 7.6 after cyclic damp heat test.

7.12 Test of Prevention Level

The tested objects are encoded locks, earth locks outdoor and computer key used indoor and outdoor.

The test is based on GB 2008. The prevention grade of outer skin is IPX4. There is no water in the interior of locks and computer key. The screen of computer key should work well. In the operation on encoded locks and earth locks based on 7.5, it should work well.

7.13 Dropping Test

The tested object is computer key.

Remove the transporting package of tested products and remain the prevention object which is normally used (such as leather cover). It should be put 1.2m high. According to three mutually perpendicular directions of the test items X, Y, Z, make the most fragile surface of screen, button, unlocking component and so on downward and make it fall down to the cement earth freely. Test one time in every direction. There should not be the phenomenon of cracking surface and damaged component. Select three arbitrary encoded locks and operate, they should work well.

7.14 Short-time and Peak Withstanding Current Test

The tested object is earth lock.

Take the product into the test circuit. The test method is based on rules of DL/T 593.

The values are:

a)Rated short-time withstanding current(valid value): 8kA

b)Rated peak withstanding current(peak value): 20kA

c)Rated short-circuit duration: 3,4s

After the test, the earth interface cannot be cut and can work well.

7.15 Mildew Test

The testing method is carried out based on the agreement between users and manufactures accord to the rules in GB/T 2423.16.

7.16 Salt Spray Test

The testing method is carried out based on the agreement between users and manufactures accord to the rules in GB/T 2423.17.

7.17 Dust Test

The testing method is carried out based on the agreement between users and manufactures accord to the rules in GB/T 2423.17.

8 Tests before Leaving Factory

The aim is to check the faults of materials and products without damaging the function and reliability of the products. The test can be done in anywhere to each product. The tests can all be done lively accord to the agreement.

The projects include:

a)appearance and structure inspection (seen in 7.2)

b)simulated operation test (seen in 7.3)

c)functional verification (seen in 7.4)

d)locking and unlocking test (seen in 7.5)

e)power frequency voltage withstanding test (seen in 7.6.3)

f)power adaptability test (seen in 7.7)

9 Selected Guide of Preventing Electric Mal-operation System with Computer

9.1 General Provisions

The point of choosing preventing electric mal-operation system with computer is to ensure the function of products and the structure and components of the products meet the operating requirements.

These requirements should consider the applicative laws and users’ safety regulations.

9.2 Selection of Rated Value

In the specific operating method, when choosing preventing electric mal-operation system with computer, the rated value of its components should meet the requirements under normal condition and condition of broken electric device or system.

The selection of rated value should meet this standard and consider the features and future of current operating way. The rated value of preventing electric mal-operation system with computer is given in the fifth chapter in this standard.

9.3 Selection of Design and Structure

When using preventing electric mal-operation system with computer, in principle, all components of high voltage electric device and attachments which may cause misusing should achieve compulsory locking function no matter it’s in the remote place or in the local place.

Preventing electric mal-operation system with computer should be reliable, simple and conveniently maintained. It should not make normal operation and accident more complex.

To breaker or disconnector and earth switch operated by electricity, in electrical locking circuit there should be the auxiliary interface of breaker or disconnector and earth switch instead of restart relay.

In addition, some technical solutions such as high-voltage electrical displaying locking device can be used to achieve compulsory locking.

10 Information Supplied during Checking, Ordering and Bidding

10.1 Information Supplied during Checking, Ordering

When checking or ordering preventing electric mal-operation system with computer, the supplier should give the following information:

a)Features of the system. The general introduction of system, operation of system, managing mode, such as main station, dimension of station, voltage grade, primary system wiring diagram, protection by man or none.

b)Using condition different from this standard (seen in third chapter in this standard). Highest and lowest temperature around, all operating condition over normal value or affecting normal operation of the device, such as abnormally exposed in steam, wet air, smog, explosive gas, excessive dust or smog, heat radiation (like sunlight) and so on.

c)Features of high voltage electric device and attachments.

1)Type and name of high voltage electric device and attachments which need to be unlocked.

2)Type and operating way of components.

d)Configuration requirements of mal-operating preventing and locking system.

1)Types of simulated terminal.

2)Types of mal-operating preventing host, such as inserted mal-operation preventing host, computer (in working station) and server.etc.

3)Locking requirements and type of locks, such as using fixed lock and/or padlock, The types of locks include mechanical encoded locks, electrical encoded locks, earth locks, remote controlling and locking device or some types among them.

4)Communication device of main station and factory station.

5)Requirements of communication connecting with other systems.

6)Other configuration requirements.

7)Configuration list of system.

Besides the projects above, inquirer should list all conditions which may affect bidding and ordering, such as special fitting and installing condition. If demanding special type test, they should provide relevant information.

10.2 Information Supplied when Bidding

When bidding, manufactures should provide the following information in the way of writing or painting:

a)Type test report. If the customers need, identifying report and information should be provided.

b)Configuration of preventing electric mal-operation system with computer.

c)Features and functions of preventing electric mal-operation system with computer, for example:

1)Specification of structure and functions.

2)Specification of technology of each component.

3)Locking scheme.

4)Largest size and installing way.

5)Quality of heaviest transporting unit.

6)Tools of transporting and installing.

7)Installing regulations.

8)Specifications of operating and maintaining.

d)List of devices which are ordered by users and components which should be ordered.

11 Rules of Transporting, Storing, Installing, Operating and Maintaining

11.1 General Provisions

The manufacturer shall provide specifications of transporting, storing, installing, operating and maintaining for preventing electric mal-operation system with computer. Transporting, storing, installing, operating and maintaining should follow the rules in specifications.

Transporting and storing specifications should be supplied in appropriate time before delivering the goods. Installing and maintaining specifications should be supplied when delivering the goods.

This standard cannot list the rules of all types of preventing electric mal-operation system with computer exhaustively. However, specifications provided by manufacturer should include the information of 11.2~11.5.

11.2 Condition of Transporting, Storing and Installing.

If manufacturer cannot ensure the using condition in contract (such as temperature and humidity) when transporting, storing and installing, it should reach a specific agreement with customers.

In order to protect the products from electricity in the process of transporting, storing and installing and prevent them become wet due to rain, snow and dew, preventing solutions should be carried out. Shake in the process of transporting should be considered. There should be rules relevant with that.

11.3 Installation

The specification of preventing electric mal-operation system with computer provided by manufacturer should include the following contents.

11.3.1 Ensemble Installing Diagram

If preventing electric mal-operation system with computer is shipped disassembly, all transporting units should be signed clearly. The ensemble installing diagram and the position displayed diagram of installing should be provided along with the system.

11.3.2 Installation

Specification of preventing electric mal-operation system with computer should include descriptions of location, basis and relevant requirements which are convenient for operating lively.

When a single product is over 100kg weight (such as vertical simulated terminal), there should be a note and information of special lifting device and lifting position.

11.3.3 Connection

There should be a specification of preventing overheating and unnecessary stress caused by connecting with high voltage electric device and attachments and controlling device. Besides, it should give some advices about electric interval.

Connections include:

a)Connection between cables.

b)Connection between encoded locks.

c)Connection between earth locks.

d)Connection between remote controlling and locking devices.

11.3.4 Test after Completing Installation

After completing the installation and connection of preventing electric mal-operation system with computer, is should be checked and tested. Manufacturer should provide specifications of checking and testing. The specifications inclu, , , de:

a)The list of advised local testing projects for correct operation.

b)The procedure which may be adjusted for correct operation.

c)Relevant measuring projects which are advised to be recorded for helping make the decision of maintain in the future.

d)Instruction about last checking and investing operation.

11.4 Operation

The specifications that manufacturer gives should include:

a)General instruction, especially technical instruction about features and operation of preventing electric mal-operation system with computer should make users know the principles involved.

b)Instructions about security performance and operation of computer key as well as locks.

c)Instructions relevant with operation in order to operate, break, earth, maintain and test.

11.5 Maintaining

11.5.1 General Provisions

Manufacturer should provide the maintaining instruction and the evaluation of maintaining time,, common faults and solutions, operating times and time of device, and the instruction that which components are checked and repaired when the operating times and time are reached. Manufacturer should provide the maintained projects, method and advices which need to be updated.

Instructions provided by manufacturer should include the contents in 11.5.2~11.5.5.

11.5.2 Lubricating

The quality requirements of lubricants and greases; the requirements of lubrication cycle.

11.5.3 Pollution and Corrosion Prevention

Instructions of cleaning and corrosion methods for various functional components.

11.5.4 Additional Components and Materials

The manufacturer shall give a list of additional components and materials. Users can store accord to the list.

11.5.5 Special Tools

If there are tools used in dismounting and overhauling, manufacturer should provide relevant list.

12 Security

Only when the preventing electric mal-operation system with computer meets the requirements of this standard, the applicable regulations as well as users’ safety regulations and is used accord to the instruction, it can run well.

Usually only designated personnel can be close to high-voltage electric device and accessory devices to operate the system.

13 Environmental Impacts of Products

The manufacturer shall provide required information about environmental impact of preventing electric mal-operation system with computer.

The manufacturer should give the necessary guidance about life of different materials and removal of procedures, and give the necessary instructions on the possibility of recycling.

a)The list of advised local testing projects for correct operation.

b)The procedure which may be adjusted for correct operation.

c)Relevant measuring projects which are advised to be recorded for helping make the decision of maintain in the future.

d)Instruction about last checking and investing operation.

11.4 Operation

The specifications that manufacturer gives should include:

a)General instruction, especially technical instruction about features and operation of preventing electric mal-operation system with computer should make users know the principles involved.

b)Instructions about security performance and operation of computer key as well as locks.

c)Instructions relevant with operation in order to operate, break, earth, maintain and test.

11.5 Maintaining

11.5.1 General Provisions

Manufacturer should provide the maintaining instruction and the evaluation of maintaining time,, common faults and solutions, operating times and time of device, and the instruction that which components are checked and repaired when the operating times and time are reached. Manufacturer should provide the maintained projects, method and advices which need to be updated.

Instructions provided by manufacturer should include the contents in 11.5.2~11.5.5.

11.5.2 Lubricating

The quality requirements of lubricants and greases; the requirements of lubrication cycle.

11.5.3 Pollution and Corrosion Prevention

Instructions of cleaning and corrosion methods for various functional components.

11.5.4 Additional Components and Materials

The manufacturer shall give a list of additional components and materials. Users can store accord to the list.

11.5.5 Special Tools

If there are tools used in dismounting and overhauling, manufacturer should provide relevant list.

12 Security

Only when the preventing electric mal-operation system with computer meets the requirements of this standard, the applicable regulations as well as users’ safety regulations and is used accord to the instruction, it can run well.

Usually only designated personnel can be close to high-voltage electric device and accessory devices to operate the system.

13 Environmental Impacts of Products

The manufacturer shall provide required information about environmental impact of preventing electric mal-operation system with computer.

The manufacturer should give the necessary guidance about life of different materials and removal of procedures, and give the necessary instructions on the possibility of recycling.

|