| China Machinery Industrial Standard—JB/T 8455-1996 | |||

| 【author/from】webmanager 【time】2016/1/12 【count】1572 | |||

|

JB/T 8455-1996

Common Technical Requirements for Mechanical

Program Lock of High-voltage Switchgear

1997-09-03 Release

1997-01-01 Implement

Mechanical Industrial Department Release

Mechanical Industrial Department

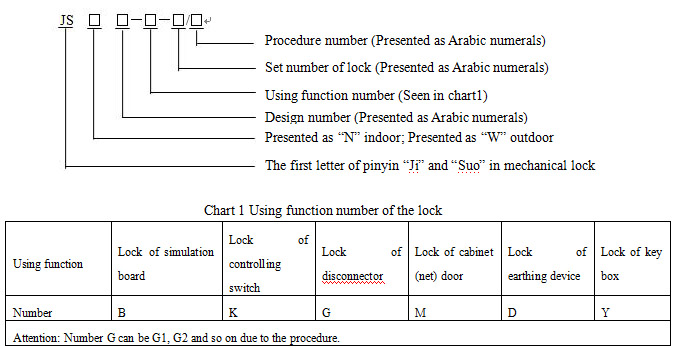

Common Technical Requirements for Mechanical Lock of High-voltage Switchgear

JB/T 8455-1996 Replace JB/DQ 2182—86

1.Range This standard specifies the definition, product type, technical requirements, test method, checking rules, packaging, transportation, storage and other content of mechanical lock used in high-voltage switchgear device. This standard is applied in high-voltage switchgear device indoor and outdoor to ensure the correctness of operating procedures, to prevent opening or closing the breaker by mistaken, to prevent opening or closing the disconnector with load by mistaken, to prevent connecting earthing device for work or closing the earth switch with electricity, to prevent closing breaker or disconnector with earthing device for work or earth switch, and to prevent getting into the electric interval by mistaken. 2.Referenced Standard The provisions contained in the following standard are used in this standard through being referenced. At the time of publication, all versions are valid. All standards will be revised. All parties who use this standard should investigate the possibility of the latest version of the following standards. GB 1720—79 Method of test for adhesion of paint films GB2423.4—81 Basic environmental testing procedures for electric and electronic products-Test Db: Damp heat, cyclic GB 3906—91 A.C.metal-enclosed switchgear for rated voltages of 3~35kV GB 4028—84 Degrees of protection provided by enclosure GB 11022—89 Common technical requirements for high-voltage switchgear JB 2111—77 Test method for bond strength of metallic coatings 3.Definition Definitions used in this standard use the following definitions besides the relevant standards and industrial rules. 3.1 Mechanical Lock of High-voltage Switchgear Device It’s the lock which meets the requirements of operating procedures in mechanical way. It consists of locking body and key for mechanical lock. 3.2 Locking Body It’s the component which has locking function and is made up of mechanical parts. 3.3 Key for Mechanical Lock It’s the component which changes the locking condition of locking body. 3.4 Procedure It performs the operating order of specified function accord to the rules. 3.5 Procedure Number The operating procedure of wiring scheme of high-voltage switchgear main circuit is consistent with the number of lock. 3.6 Vacant Procedure After mechanical lock runs accord to the command, the locked object doesn’t change the original condition, and mechanical lock can still run. 3.7 Handful (of Lock) It’s the quantity unit of mechanical locks. 3.8 Set (of Lock) It’s the quantity unit of the combinations of mechanical locks which have procedure relations. 3.9 Unlocking It cancels the locking condition of locking body through the specific tools (including the mastering key) 3.10 Mutual Unlocking It’s the condition that the lock is unlocked by the other key. 3.11 Unlocking Angle It’s the angle that key must rotate to change the locking condition of locks. 4.Product Type 4.1 Here are the type and its definitions:  4.2 Type Example of Mechanical lock Lock of controlling switch, the third set of procedure is “2”, and then the type is: JSN1—K—3/2 5.Technical Requirements 5.1 Environmental condition 5.1.1 The normal using condition is based on the rules in GB 11022. 5.1.2 The using environment of products which are used under serious environmental condition should comply with design 1 and 2 in GB 3906. 5.2 Using performance 5.2.1 Mechanical lock should be simple, reliable, operated flexibly and maintained conveniently. It doesn’t allow being unlocked by other things. It satisfies the requirements of mal-operation prevention. When the locks are dismantled, the normal operation of high-voltage switchgear should not be affected. 5.2.2 The structure of mechanical lock should meet the requirements of procedures, while the guiding position of key should be correct and the procedure should not be vacant. 5.2.3 Mechanical lock should have set number and procedure number. Lock body should have the sign of key position and rotating direction. It should also have sign of key which is used by users. 5.2.4 The lock core should be made up of the metal materials which have enough mechanical intensity and are not easily corroded. Rain preventing cover should have a good function of sealing. 5.2.5 The route of lock tongue should meet the requirements of installed switchgear. The route should have the following dimensions: 12.5, 14, 16, 18, 20, 22.4, 25mm. 5.2.6 For better maintaining, keys of mechanical locks which have the same name, type and number can be interchanged. 5.2.7 Mechanical locks should prevent wetting, mildewing, rusting and dust. The outdoor products should have the solution of preventing rain. The design and production of mechanical lock under serious condition should obey the relevant standard. 5.2.8 The thread size of lock body coordinated with disconnector should be used together with the internal thread size of operating handle. The size is M16*1.5. 5.2.9 Mechanical locks should have the function of unlocking. (including the mastering key) 5.2.10 The reliability should meet the following requirements. 5.2.10.1 50 sets of locks supplied at the same time should not do mutual unlocking. 5.2.10.2 The unlocking angle of keys of mechanical locks should be more than 30°. 5.2.11 The firmness should meet the following requirements. 5.2.11.1 Lock body should be installed firmly. After bearing 500N static tension, the screw is not loose and can still be used. 5.2.11.2 The key bears 2N•m of torques. After 30 seconds, torsion angle of plastic deformation is less than 3°. 5.2.11.3 Mechanical life of single mechanical lock is more than 10000 times. It won’t be out of shape after mechanical life test. It can be used normally without checking. 5.2.11.4 More than 2000 times of mechanical life operation should be done on each set of mechanical locks. The movement of the key should be flexible without locking. 5.2.11.5 Each set of mechanical locks should do more than 50 times of none-procedure operation. 2N•m of torques should be added to the key in the operation. 1.3 to 1.5 times of normal operation strength will be added on the switchgear. In the test switchgear cannot be operated. It won’t be out of shape after mechanical life test. It can be used normally without checking. 5.2.11.6 Pin tumbler mechanism. When the rivet of pin tumbler hole bears 150N static thrust, it should not be pulled out. 5.2.11.7 The diameter of lock tongue is 10 or 12mm. Lock tongue should meet the mechanical intensity of locked switchgear when opening or closing. 5.2.12 Flexibility should meet the following requirements. 5.2.12.1 The key should insert and extract smoothly. Lock tongue should be flexible and without locking when opening or closing at the frequency of 15 to 18 times per minute. 5.2.12.2 The extracting static tension of the key should be less than 6.4N, and the inserting static thrust is not greater than 7.4N. The inserting and extracting static thrust of closed central line type of key should be less than 9.3N. 5.2.13 Appearance should meet the following requirements. 5.2.13.1 The appearance of the lock should be beautiful. 5.2.13.2 Trademarks, handwritings, and lines of the key and lock body should be clear and correct. 6 Testing Method 6.1 Checking of appearance 6.1.1 When checking the mechanical sign by eyesight, trademarks, handwritings and lines should be clear and correct. It should meet the standard of 5.2.13.1. 6.1.2 Adhesion of paint films is inspected on the basis of GB1720, and coating adhesion is inspected on the basis of JB2111. 6.2 General inspection 6.2.1 The length and diameter of lock tongue measured by vernier caliper should meet the rules of 5.2.5 and 5.2.11.7. 6.2.2 Select five pairs of mechanical locks which have the same names, types and numbers and select five kinds of locks which have different functions to do the interchanging inspection. The progress should meet the requirements of interchanging. 6.2.3 Check the unlocking device. It can be unlocked by specific tools. 6.3 Reliability test 6.3.1 In every 50 sets of locks (usually more than 250 handfuls), each key will be used to open the lock core which has different number. One key is for only one lock. 6.3.2 The unlocking angle measured by protractor is more than 20. 6.4 Firmness test 6.4.1 Lock body is installed accord to the real working position. When the strength on the lock body is gradually added to 500N by tensile testing machine, the screws shouldn’t be loosened, and the lock body should not be broken. 6.4.2 After measuring the torque of the key by wrench, put the key into the lock core and plug the clamping chuck. At first, measure the twirling angle by normal operating strength and then use the wrench to make the torque reach the predetermined value, the lock should not have obvious deformation. 6.4.3 Install the tested objects accord to the real working position, and do 10000 times of mechanical life test by life testing machine and manual method, the key inserting to open and extracting after closing is regarded as one time. When using one key to keep opening and closing at the frequency of 15 to 18 times per minute, it should be flexible. In the testing process, lubrication is allowed. 6.4.4 Install the whole magnetic mechanical lock on the switchgear to do 2000 times of procedure operation, which should meet the requirements in 5.2.11.4. Accord to the rules and requirements in 5.2.11.5, 50 times of non-procedure operations should be done, the damage of components, permanent deformation and other faults which will affect the normal operation should not appear on the mechanical lock after the test, and mechanical lock cannot be adjusted in the test (except lubrication ). 6.4.5 When adding the thrust to 150N gradually on the rivet of pin tumbler lock, the rivet should not loose or not to be ejected. 6.5 Flexibility test 6.5.1 Each key should keep the cycle of “insert-rotate to specified angle-back to the starting position” for 50 times. The operation should be flexible. 6.5.2 Use the key insertion force tester to test on the basis of 5.2.12.2. It should meet the requirements. 6.6 Moist test It must obey the rules of GB2423.4. The high temperature indoor of severe grade is 40℃. The temperature outdoor is 55℃. The test period is 2 days. 6.7 Rain preventing test The outdoor locks in the rain preventing test should be installed on the high-voltage switchgear device. The test should meet the standard of rain preventing test on locked high-voltage switchgear. 6.8 Dust preventing test It uses the test method in the rule 6.5 of GB4028. 7 Inspection Rules 7.1 Programs in type test a) Appearance inspection b) Normal inspection c) Reliability test d) Fastness test e) Flexibility test f) Moist test g) Rain preventing test h) Dust preventing test 7.2 Type test should be done under the following conditions: a) New trial products b) Trial products in other factories c) When the important change happens on the materials in design, craft or use affects the performance of products, the corresponding type test should be done. d) The normal produced products should do the fastness test, reliability test and flexibility test for one time every 3 years. 7.3 Test programs before leaving factories Mechanical locks should do the inspection test before leaving factories. Here are the programs: a)Appearance test, which obeys 6.1.1 b)Normal programs inspection, which obeys 6.2.1 and 6.2.3 c)Reliability test, which obeys 6.3 d)Fastness test, which obeys 6.4.1, 6.4.2, and 6.4.4. However, the procedure and non-procedure operation in 6.4.4 should be done for 5 times. e)Flexibility test, which obeys 6.5.1 8 Sign, Package, Transportation and Storage. 8.1 Sign 8.1.1 Nameplate Each handful of lock should have the following signs: a)The name of manufacture and trademark; b)The type of products c)The number before leaving factories d)Produced year and month 8.1.2 Packaging Logo a)The name of manufacture and trademark; b)The name and type of product; c)The number; d)Net weight and packaging GW of the product; e)The dimension of packaging box; f)Receiving unit and address; g)Packing date and box number; h)Packaging and storage pictorial sign, such as “”,””. 8.2 Packaging - Pictorial marking for handling of goods, such as “Handle With Care.”, “Keep Dry.” 8.2.1 One set of locks should be packaged together. 8.2.2 The packaging box should prevent the components of the locks from damaging, losing, deformation, moisture and corrosion. 8.2.3 Each set of locks should have a certificate of products and instructions of procedures. Each packaging box should have the installing specification. 8.3 Transportation The packaging box of locks should meet the requirements of transporting and loading. 8.4 Storage The lock should be stored after finishing packaging. The environmental condition of storing place should meet the using condition of products. Additional Instructions: This standard is raised by National High-voltage Switchgear Standardization Technical Committee. Hunan switchgear factory is responsible for the draft of this standard. This standard was drafted by: Xi'an High Voltage Apparatus Research Institute, EPRI switch Institute, Beijing Switch Factory, Tianshui Changcheng Switchgear Factory, Suzhou Switch Factory, Dalian lock Factory, Nanyang Hikaru Instrument Factory, Zhenjiang Electric device Factory. The main drafter of this standard: GaoChen, Liao Yiwei, Liu Qingqing | |||

| 【close】 |